Design of Seawall with Limestone Calcined Clay Cement (LC3) and Reactive Magnesia Cement (RMC), Calcined Limestone

Students: Abdulrahman I. Kh. AlTantawi, Hamza Ansari, Shaheer Haider

Professor: Kemal Celik

Concrete is the most widely used construction material, yet its ubiquitous presence also poses serious environmental challenges and concerns. Ordinary Portland cement (OPC), the primary binding agent in concrete requires intense energy for production and gives rise to an average CO2 emission of 900 kg/tonne due to fuel combustion and decomposition of CaCO3 during the calcination process. With an annual global production of 4.1 billion tonnes in 2019, the cement industry is estimated to emit 3.0 billion tonnes of CO2 (assuming 80 clinker content), accounting for 7.6% of the annual anthropogenic CO2 emission of 39.2 billion tonnes. To mitigate the environmental footprint of OPC-based concrete, a combination of limestone powder and calcined kaolinitic clay can be used to replace clinker-based cement at large proportions. The limestone and clay are widely available around the globe and can be easily processed with the existing infrastructure of typical OPC plants, thus requiring little capital investment. Also, this emerging ternary mixture is capable of enhancing the composite performance with regard to mechanical and durability properties.

Durability is of immense importance when designing new sustainable, cost-effective, and environmentally friendly materials. A lesser durable concrete will lead to frequent maintenance and repair, thus leading to economic costs and an increased carbon footprint. The highly humid environment of the UAE’s shoreline increases the corrosion vulnerability of the coastal infrastructures in which reinforcing bars are embedded. Corrosion reaction produces corrosion products of larger volume in comparison to the parent metal, and this causes distress, cracking, and spalling which consequentially compromises the load-carrying capacity of the structure. Load-induced cracking serves as a pathway for the ingress of aggressive ions such as chloride and moisture to reach the rebar surface, thus initiating the corrosion process. To mitigate this effect discontinuous synthetic fibers are introduced into the matrix.

Students involved in this project will enhance skills that are not limited to but include Engineering design, advanced knowledge in Solid Works, Ansys, Abaqus and SAP, Concrete mixture design, performance-based design, Techniques such as calorimetry, mechanical property characterization, X-ray diffraction (XRD), thermal gravimetric analysis (TGA), and scanning electron microscopy (SEM).

The methodological approach will be as follows:

1) Preparing the formulation, trials, and testing of sea walls panel with LC3, RMC, and calcined-limestone, including fiber reinforcement

2) Enhancing surface complexity of sea walls,

3) Creating a test set up to test the durability and design of the seawall built using the mixture in the lab

4) Implementation of produced seawalls to the Abu Dhabi’s marina,

5) Characterizing and performance testing of seawalls before and after the installation to the shoreline,

6) Writing technical report

Economic Analysis of Energy and Purple Hydrogen Generation from Municipal Sewage Waste Using Microwave-induced Plasma Gasification Technology

Student: Elvira Selivanova

Professor: Philip Panicker

Sewage sludge treatment and disposal represent one of the most important issues for environmental management in the modern world. It contains pharmaceutical compounds and cleaning chemicals that through the water bodies severely affect the health of organisms and also humans. Sewage, both untreated and treated, also releases large quantities of greenhouse gasses, including methane, hydrogen sulfide, and carbon dioxide, into the atmosphere. Microwave-Induced Plasma gasification technology (MIPGT) offers the best technological solution that could prevent the damage caused to the environment due to the disposal of the sewage by simply consuming it close to the source of the flow.

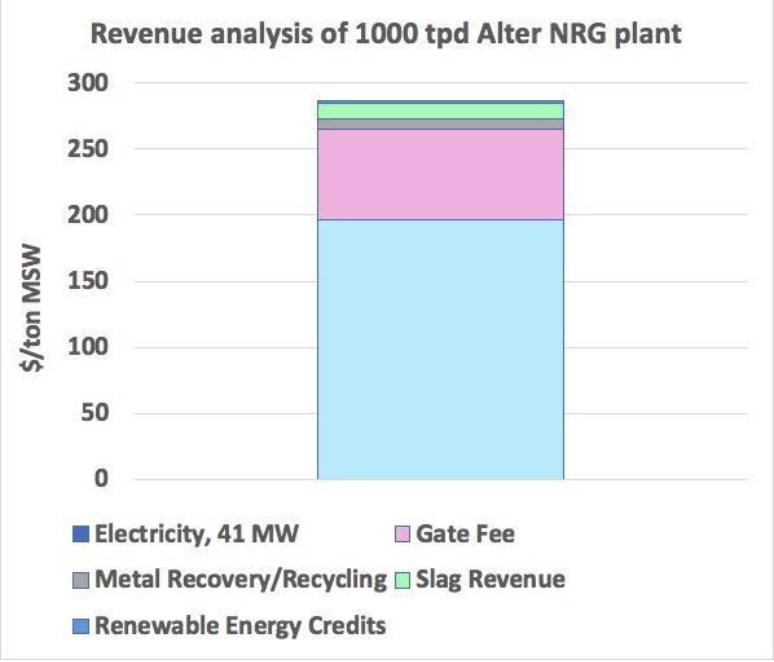

Using the evidence from the scientific literature, it is objectively clear right now that PGT is an effective solution to solving the problem of sewage waste disposal and subsequent energy generation. However, for the successful wider adoption and implementation of PGT in the marketplace of“waste to energy” technologies it is important to understand whether the technology can be economically effective. After the analysis of 50+ scientific papers about the techno-economic analysis of PGT and performing calculations of the technology’s costs and revenues, it has been identified that there exists a possibility of the generated profit by a PGT waste-to-energy plant. Moreover, the technology has the potential to have a positive NPV in the period from 12 to 20 years (the average lifetime of the plant), meaning that the technology can grab the attention of the investors not only as the sustainable approach towards waste treatment and clean energy generation but also as a promising long-term investment project.

One of the distinctive features of PGT is that it enables the extraction of highly pure hydrogen from syngas. During the process of researching the topic of hydrogen, it was found that hydrogen is classified by color for ease of remembering and is based on the processes of producing it. For example, blue hydrogen is formed by steam reformation of natural gas or coal, while green hydrogen is formed by the electrolysis of water using electricity generated using renewable energy. For this reason, we decided to come up with a new color of hydrogen called “purple” which would mean the hydrogen that was generated using plasma technologies such as plasma gasification of wastes. It would also be an apt color for clean hydrogen for a circular economy as purple is the color associated with NYU. Due to the emergence of the market for the extraction of hydrogen using PGT, the prices for the “purple” hydrogen are projected to be on the competitive level according to the promises of the companies.

PGT and MIPGT show the greatest potential within the waste-to-energy domain for efficiency, effectiveness, for enabling zero-waste-to-landfills, and for a completely circular economy, thereby bringing about cleaner environments, sustainable cities, and solutions for ameliorating climate change. In order to enable faster development and adoption of plasma gasification, it is crucial to implement economies of scale for increasing the numbers of PGT plants (large and small-sized plants) and therefore, lowering the costs.